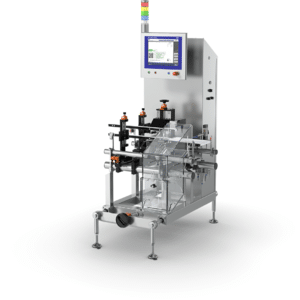

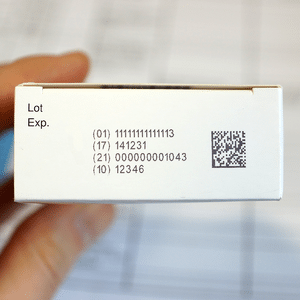

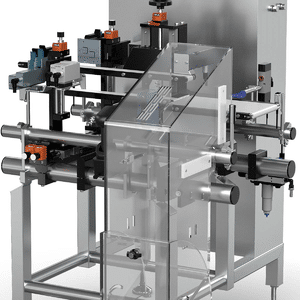

Compact serialization system for easy integration into production lines. Performs all functions for serialization, including the marking, recording, and verification of all serialization data.

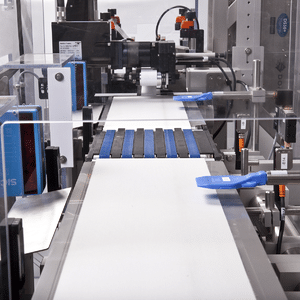

Fully Automated Processing

Automated item-by-item serialization with advanced tracking, precise printing, and quality verification.

Efficient Product Handling

High production line speeds up to 400 ppm for a wide range of package sizes and easy product changeovers – product handling at its best.

Compact and Space Saving Design

At just 944mm wide, it is designed to use minimal production line space. Ideal for any production environment.

| Track & Trace Solution | Serialization |

| Product Types | Cartons Oriented |

| System Design | automated |

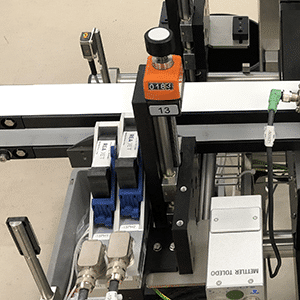

| Reading Devices | Smart Camera |

| Number of Reading Devices | up to 2 |

| Throughput | up to 400 ppm |

| Compatible Software | PLM Direct PLM Serialization |

| Dimensions (H x W x D) | variant 150: 2059 x 944 x 1329 mm |

| Product Height | 10 – 200 mm |

| Product Width | 45 – 200 mm |

| Product Length | Variant 250: 25 – 250 mm Variant 150: 25 – 150 mm |

| HMI | 15″ 15″” |

Choose printers and Smart Camera options as needed to help ensure products are compliant with the current regulations.

Advanced countercheck sensors help ensure that only products that meet the standards for quality are kept in the good path of the production line.

Evaluate datamatrix codes in line with ISO 15415 guidelines. Validate the print quality during the production process for advanced line performance.

With easily-accessible parts for cleaning and maintenance, the system is in compliance with Good Manufacturing Processes (GMP).

Use PCE Line Manager (PLM) software for complete line control of production processes for serialization. Choose PCE Site Manager (PSM) for enterprise integration with site-wide IT infrastructure.

Meets current regulatory requirements and is easily upgradeable for future requirements and regulations. As regulations change, simple and quick software updates help protect the hardware investment in the long-term.

A global network of service experts provides fast remote and on-site support. Our comprehensive service offering allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.